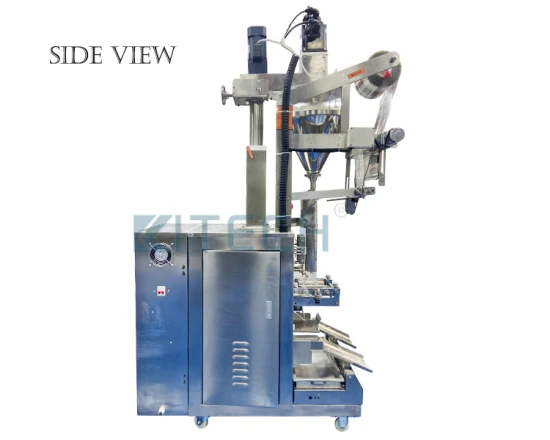

Hot Dog Filler Machine Sausage Filling Automatic Sausage Making Machine

Package size per unit product 108.00cm * 100.00cm * 169.00cm Gross weight per unit product 180.000kg Main Parameters: De

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | GS-30B |

| Process | Making |

| Automatic Grade | Semi-Automatic |

| Type | Sausage Making |

| Voltage | 220V |

| Customized | Customized |

| Net Weight | 150kg |

| Capacity | 400-500kg/H |

| Bucket Capacity | 65L |

| Enena Tube Diameter | 12mm/19mm/22mm/32mm |

| Transport Package | Strong Standard Export Plywood Case |

| Specification | 980*900*1590mm |

| Trademark | fengxiang |

| Origin | Guangdong, China (Mainland) |

| HS Code | 84385000 |

| Production Capacity | 100sets/Month |

Packaging & Delivery

Package size per unit product 108.00cm * 100.00cm * 169.00cm Gross weight per unit product 180.000kgProduct Description

Main Parameters:

Product Name | Sausage Filling Machine | Power | 1.5kw |

Pump pressure | 2.5 mpa | Capacity | 400-500kg/h |

Dimension(mm) | 980*900*1590 | Net Weight | 150kg |

Voltage | 220v | Enema tube | 12/19/22/32 mm |

Details about the machine:

The sausage filling machine is essential equipment for processing sausage products. It can make large, medium and small bowel products of various specifications. The machine appearance is beautiful, well-made, easy to operate, safe and of reliable use. The machine's hopper, valves, enema tube and the outer packing are all made of high quality stainless steel and line with the food hygienic requirement.

Feature:

This machine mainly consists of frame, hopper, working cylinder, oil cylinder, hydraulic operating system and electrical system. Through the lever or handle (user options or manual ball valve pneumatic ball valve), control the reciprocating movement of the piston, absorption and packed material, to achieve continuous enema.

Finished Goods:Certifications:

Packaging & Shipping:Company Information:

Zhaoqing Fengxiang food machinery factory is founded in 2005, located in Zhaoqing, Guangdong province, which covers 6000 square meters. Our company engaged in providing and developing the following range of professional equipment and engineering services:

1) Vegetable processing, meat processing and production lines for catering enterprise.

2) Agricultural plant production line.

3)Full range of equipment of large canteen, central kitchen.

Welcome to visite our factory and trust us.

FAQ

- 1.HOW LONG CAN I GET THE FEEDBACKS AFTER WE SENT THE INQUIRY?

We will reply you within 8 hours in working day.

- 2.ARE YOU A DIRECT MANUFACTURER OR TRADING COMPANY?

We are a factory, we also have our own international trade department.

- 3.WHAT PRODUCTS CAN YOU OFFER?

We mainly produce equipment for vegetable,fruits,meat and fish etc.

- 4.WHAT APPLICATIONS DO YOUR PRODUCTS RELATE TO?

Our products involve many industries, such as food factory,food shops,supermarket,restaurant and university dining hall.

- 5.CAN YOU DO CUSTOMIZED PRODUCTS?

Yes,we are mainly doing customized products according to the customers' drawings.

- 6.HOW ABOUT THE CAPACITY OF YOUR COMPANY?

Production capacity is about 800 units machines per year.

- 7.HOW MANY EMPLOYEES OF YOUR COMANY?WHAT ABOUT THE TECHNICISTS?

We now have more than 150 employees, including 10 engineers and 10 technicians.

- 8.HOW TO GUARANTEE THE QUALITY OF YOUR GOODS?

Firstly,we will do the inspection after every process.For the finished machines,we will do 100% inspection according to the customers' requirements and the international standard.

- 9.WHAT'S THE PAYMENT TERM?

When we quote for you,we will confirm with you the way of transaction,FOB,CIF,CNF,etc.For mass production machines, you need to pay 30% deposit before producing and 70% balance before shipment.

The most common way is by T/T. L/C is also acceptable.

Related Products

-

![Meat Chopper Mixer/Cutting Mixer / Meat Cutter Mixer]()

Meat Chopper Mixer/Cutting Mixer / Meat Cutter Mixer

-

![Automatic Soft Sausage Type Silicone Sealant Adhesive Filling Sealing Machine]()

Automatic Soft Sausage Type Silicone Sealant Adhesive Filling Sealing Machine

-

![Automatic Quantitative 4 Side Seal Pillow Tea Plastic Bag Packaging Machine Filling Sealing Machine Price]()

Automatic Quantitative 4 Side Seal Pillow Tea Plastic Bag Packaging Machine Filling Sealing Machine Price

-

![Automatic Vertical Auger Filler Form Fill Seal Seasoning Sugar Flour Matcha Tea Powder Milk Powder Sachet Wrapping Packaging Packing Filling Sealing Machine]()

Automatic Vertical Auger Filler Form Fill Seal Seasoning Sugar Flour Matcha Tea Powder Milk Powder Sachet Wrapping Packaging Packing Filling Sealing Machine